Can You Ship Wood Crates? Essential Tips for Safe Transport

There are currently over a billion dollars worth of wooden crates being shipped from place to place all over the globe. Their contents are an assortment of items from bottles of fine wine to – judging by the image above – something that should be handled with the utmost care. As current trends stand, wooden crates will still be widely used well into the future.

So, yes, wooden shipping crates in Melbourne and other places can be shipped, whether within or outside a country’s borders. However, while being shippable is one thing, proper shipping is another. Despite the crates’ solid construction and versatility, using the wrong crate or packing the contents haphazardly can lead to logistical headaches.

When thinking about shipping your goods with wooden shipping crates, consider the following tips:

Use ISPM-15-Certified Crates

Unfortunately, timber crates and pallets are a typical method by which pests and other invasive species travel from one ecosystem to another. Carpenter ants and termites, to name a few, feed on the timber to sustain themselves throughout the journey, which also undermines the crate and pallet’s integrity.

In addition, many countries, including Australia, are unwavering about preventing invasive species from setting foot on their territories. Introducing just one of them can throw off the local ecology as it competes with other native species for natural resources. According to a report by the Intergovernmental Science-Policy Platform on Biodiversity and Ecosystem Statistics (IPBES), invasive species cost the world economy over USD$400 billion in 2019.

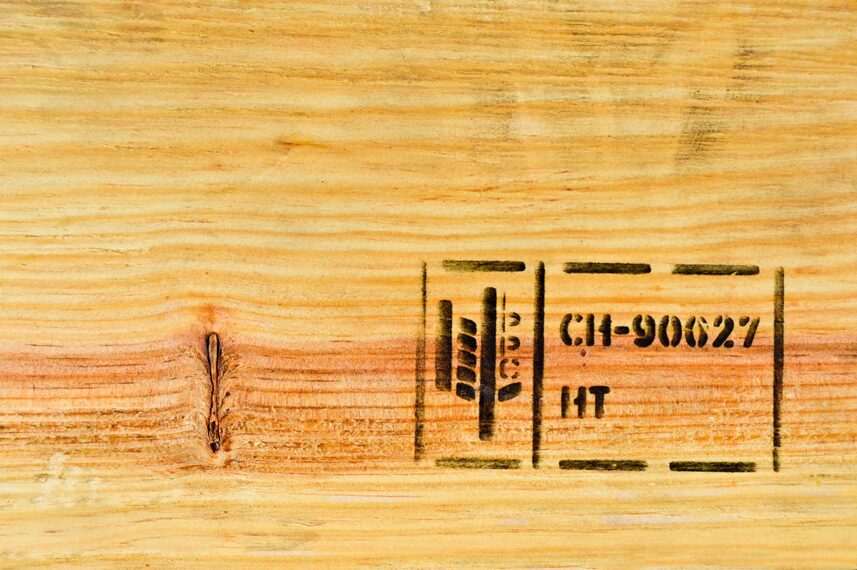

In light of this, world governments have required wooden packaging products for global trade to comply with ISPM-15 guidelines and other international shipping standards. Timber crates that adhere to this standard are highly resistant to pest infestation, preventing them from propagating elsewhere. You can check a crate’s compliance by looking for an engraved or stamped IPPC seal on its surface.

Not all wooden packaging solutions are required to comply with ISPM-15. These include:

- Wooden cases and crates with a thickness of 6 mm or less

- Packaging products made from processed wood material, such as plywood

- Wooden gift boxes that were made with practices that render them pest-free

The price of using non-compliant wooden crates or even ones with illegible IPPC seals can be steep. Customs may penalise the business several times the overall value of the goods inside the non-compliant crates.

Optimise Actual and Dimensional Weight

In the logistics industry, there are two metrics worth remembering as a business owner: actual weight and dimensional weight. Most logistics services bill the higher of the two, which can put the business at a disadvantage in terms of freight cost.

Actual WeightAs the term implies, the actual weight is the weight of the package, as shown on a weighing scale. |

Dimensional WeightAlso called volumetric weight, dimensional weight is the package’s weight relative to its shape and size. |

Logistics companies shift between these two because of the nature of cargo. Fully packed cases and crates add stress to trucks and other modes of transportation, while lighter cargo in larger containers eats up space and reduces the amount of cargo a logistical run can carry. Maximising their runs is simply in the interest of cost-effectiveness.

When a cargo reaches the maximum allowable weight for shipping, it’s “weighted out.” On the other hand, a cargo whose volume exceeds its actual weight has “cubed out.” Getting charged for either is inevitable, but you can make the most out of the crate space to deliver as many goods in as few runs as possible.

This also works from a safety standpoint, as empty space risks rocking the goods back and forth during transit and causing damage. It’s why sensitive machinery and fragile items are secured with heavy-duty straps or custom wooden crates with internal casings.

Some countries require reducing empty space. In Australia, depending on the product, the limit can be between 25% and 40% of the wooden crate’s volume. In many European Union countries, businesses are required to submit a package reduction plan first.

Use Pallets for Easier Movement

Wooden crates and pallets go together like fish and chips, not because they’re both made out of the same material. Most crate designs lack the collars that enable them to be moved by forklifts or pallet jacks. More importantly, without a pallet, storage facility personnel will have to transport crates by a few instead of dozens, which isn’t an ideal use of resources.

Due to their construction, wooden pallets are the unsung heroes of economies around the world. As we mentioned in our last piece on common packaging supplies, a standard wooden pallet can bear up to 6,000 lbs (2,722 kg) of cargo. A few hundred of them are enough to move an entire distribution centre’s worth of goods within and beyond.

Wooden pallets can be produced in a wide range of sizes, with the Australian standard pallet (also called an Industry Standard pallet) being 1.165 x 1.165 metres. This pallet is configured in a two-way design that allows moving equipment to insert its prongs from any side. As pallets are covered under ISPM-15, they have to be certified to export crates overseas.

Conclusion

When used properly, wooden crates can be a great choice for your business. It’s no surprise that they still fulfil modern shipping needs even as more durable counterparts like metal are available. We at Safe Pack hope that your goods reach their destination in mint condition with these tips.